DuFor and Ultrapolymers had known each other for years. In 2014, their collaboration gained momentum at exactly the right time. During a meeting that year, the discussion turned to the potential of DuFor’s specialty polyesters for injection molding applications.

Curious how this partnership evolved and what it means for the market? Keep reading.

From concept to collaboration

Although DuFor had previously explored injection molding applications, the idea had never been fully developed. For Ultrapolymers, active across Europe and deeply connected to the injection molding market, the opportunity felt like a natural fit. A shared interest in innovative applications created the foundation for a stronger partnership.

It was agreed that Ultrapolymers would represent DuFor’s portfolio throughout Europe, with a clear focus on injection molding solutions. After an initial phase of market research and application development, the partnership became official in 2017. Since then, new applications have been introduced step by step, and volumes have grown steadily.

From material to market

Ultrapolymers operates as a distributor for a broad range of materials, while DuFor provides specialty polyesters that deliver unique performance in specific applications. By combining expertise, the companies have successfully launched solutions across multiple markets, ranging from cosmetic packaging and furniture components to dress guards for e-bikes and industrial water filters.

A shared commitment to sustainability

This collaboration is driven not only by market opportunities but also by a common vision. Ultrapolymers prioritizes sustainable materials and innovation, responding to growing demand for circular, safe, and future-proof solutions. DuFor’s product development and ReSpec vision aligns seamlessly with this approach: offering antimony-free polyesters and introducing Recycled CumaPET for injection molding applications, all designed with sustainability and performance in mind.

The winning formula

What makes this partnership so effective is complementarity. DuFor brings deep technical expertise, flexibility, and a strong customer focus. Local production and short communication lines enable fast, efficient collaboration, qualities that Ultrapolymers values highly in a partner committed to joint material development.

What’s next

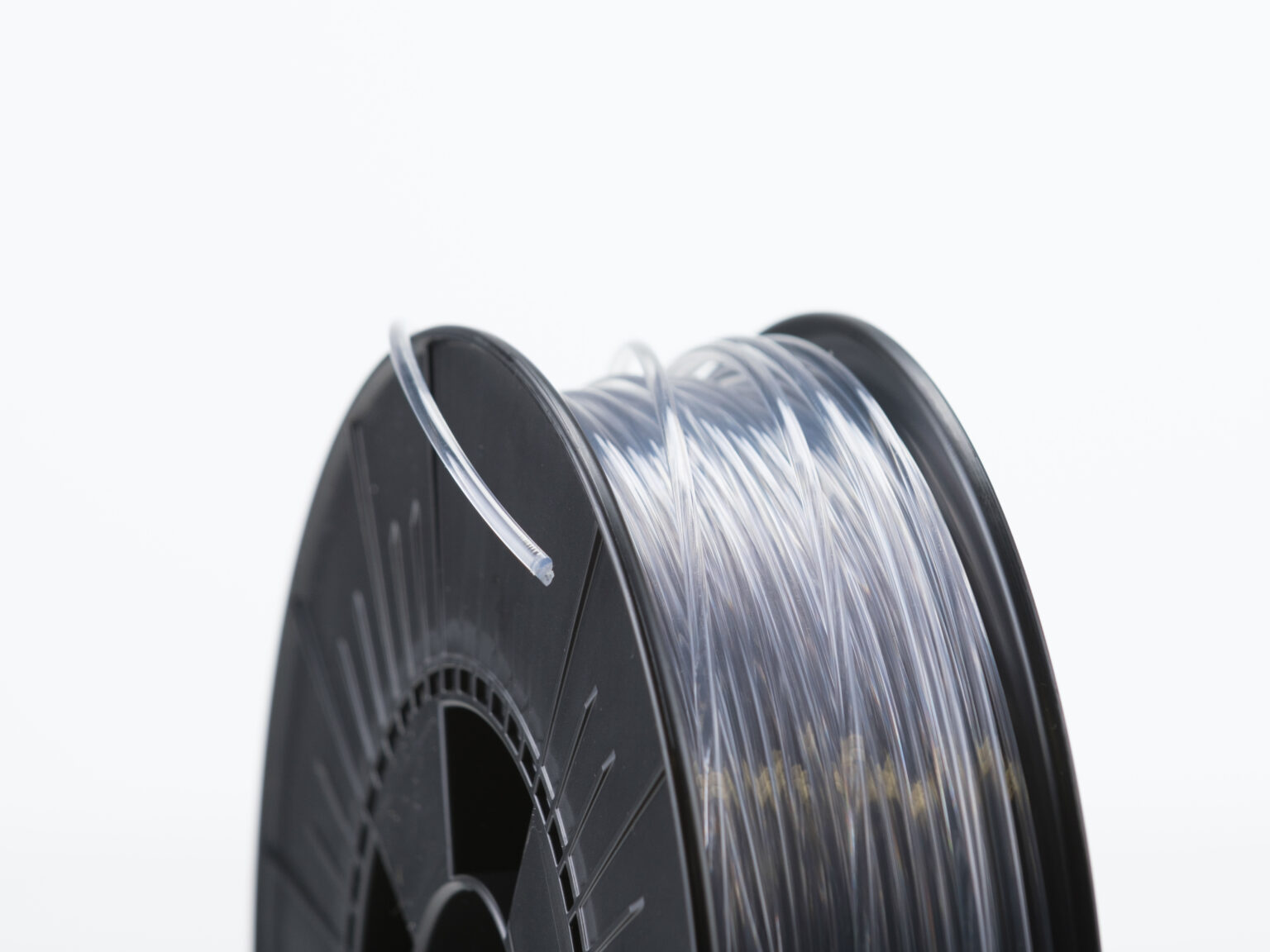

DuFor’s specialty polyesters offer properties that are increasingly critical in Ultrapolymers’ markets: sustainability, transparency, food safety, processability for injection molding, and the use of rPET. Cleanliness and migration have become even more important in recent years, and DuFor, with BPA-free and antimony-free grades, plays a key role in meeting these requirements.

The ambition is clear: to continue expanding this successful collaboration and deliver more high-quality applications where DuFor’s specialty polyesters make the difference. In our next article, we’ll showcase some of these applications—from caps to dress guards for e-bikes.

Want to see how specialty polyesters transform end products? Stay tuned to our news page or our LinkedIn.

Are you curious how we can assist you? Contact one of our specialists. They will be happy to tell you more about the possibilities.